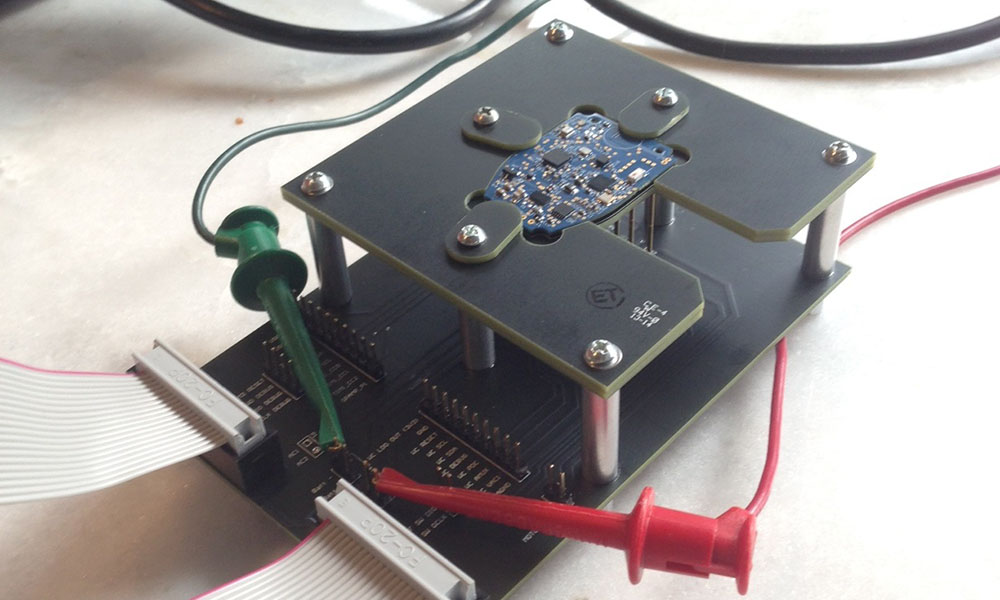

PCB ASSEMBLY(PCBA) SERVICES

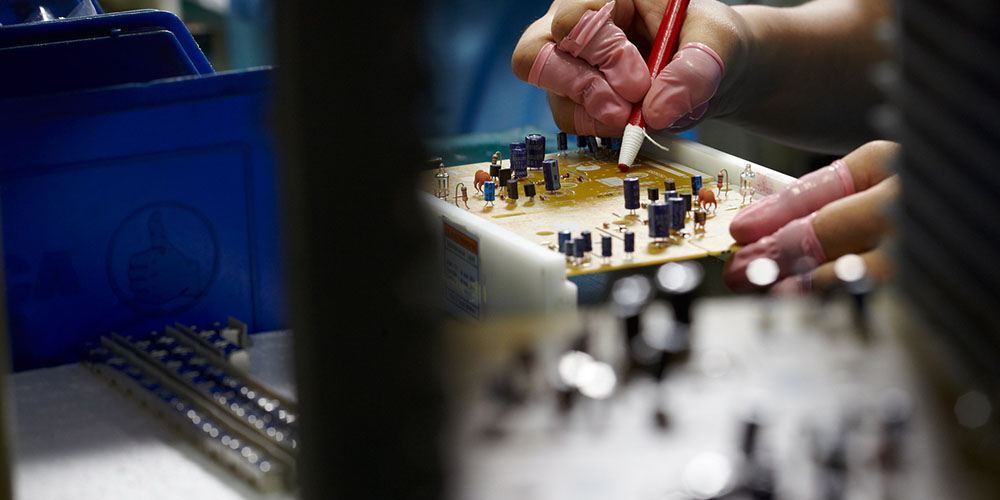

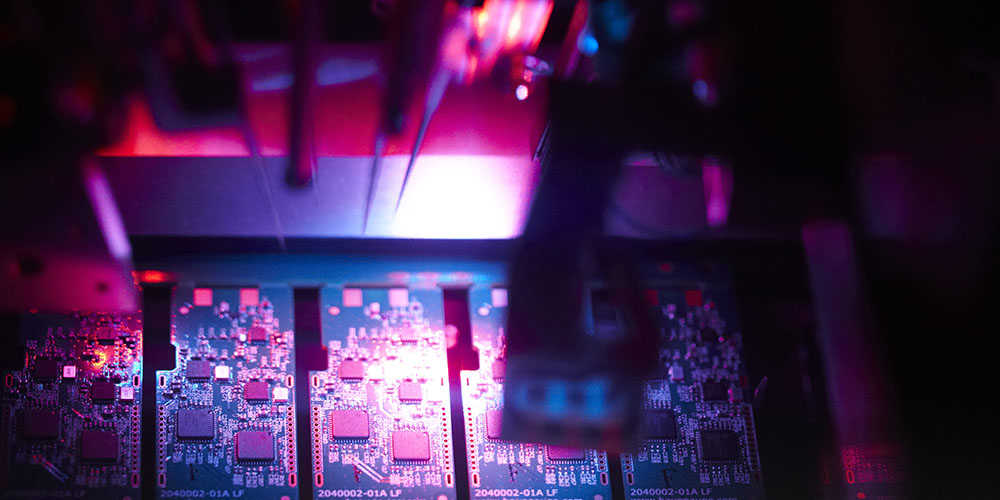

Jinghon Electronics Limited is major in printed circuit board assembly (PCBA) for more than 19 years. We can provide one-stop PCBA Service, Such as 0201/BGA/CCGA Surface-mount (SMT), Thru-hole (THT), mixed Technology (SMT & Thru-hole), Conformal Coating, Potting and Encapsulations, AOI/X-RAY PCBA Testing, IC Programming, Box Building Service, etc. The PCBA used in TELECOMMUNICATIONS, AUTOMOTIVE ELECTRONICS, 3G/4G/5G PRODUCTS, IOT Products, AI Smart Control Products, RF, NETWORKING, SECURITY, INDUSTRIAL CONTROL, MEDICAL, INSTRUMENTATION INSTRUMENTATION, MILITARY PRODUCTS, COMPUTER PERIPHERALS AND OTHER HIGH-TECH FIELDS. We have Great reputation from our customer around the world.

CAPABILITY

| Item # | Item Name | PCBA Capability |

| 1 | Assembly Options | Surface Mount (SMT), Thru-Hole (THT), Box building, COB, Conformal Coating, Potting and Encapsulations ,IC PROGRAMMING &MARKING GRINDING & LETTERING |

| 2 | Types of Solder | leaded and lead-free (RoHS Compliant) PCB assembly services |

| 3 | Stencils | laser cut stainless steel stencils |

| 4 | Minimum Order | 1 pieces |

| 5 | Component Size | Passive Component: we can accept components as small as 01005, 0201, |

| BGA: We have the ability to handle BGA of 0.25mm pitch with X-ray testing. | ||

| Fine Pitch Parts: we can assemble 0.25mm fine pitch parts.POP(Package on Package), QFP,CCGA,CSP,etc. | ||

| Max Component Height: 25mm(SMT), Top 120mm/Bot 15mm (Wave-Solder) | ||

| 8 | Component Package | We accept parts in Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk. |

| 9 | Board Dimension | Min Board Size: No Limited |

| Max Board Size: 680mm x 500mm | ||

| 11 | Board Shape | We can assemble boards in Rectangular, Circular and any Odd Shapes. |

| 12 | Board Type | Rigid PCB, Flexible PCB, Rigid-flex PCB, Metal PCB |

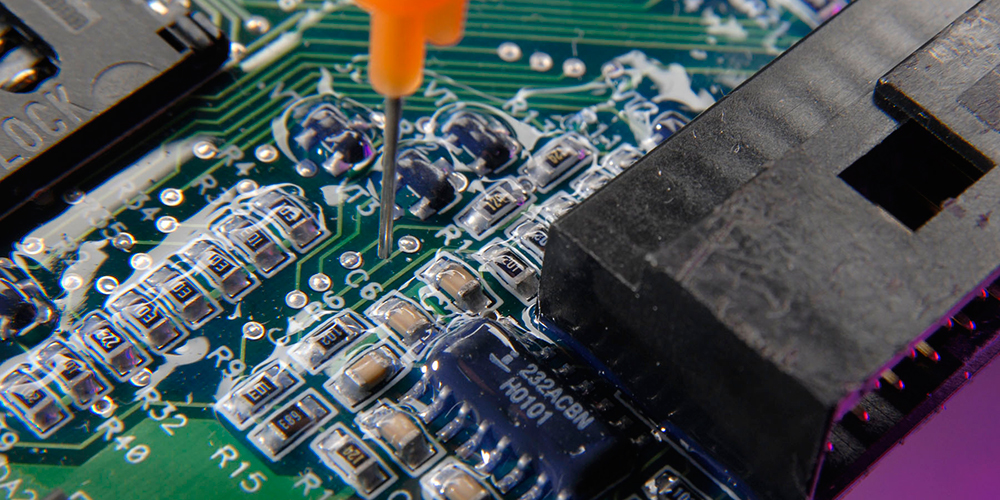

| 13 | Repair & Rework | Repair and rework accepted. Our BGA reballing service with which we can safely remove the misplaced BGA, reball it and put it back on the PCB correctly. It is cost-effective. |

| 14 | Testing | ICT, AOI, X-Ray, Function Test (FCT) ,Aging Test. |

| 15 | Output | 12SMT LINE 5DIP LINE |

| 16 | Quality Standard | IPC-A-610E, ISO 13485:2003 ,ISO 16949:2011, ISO 14001:2004 |